M2.6 Screw & Bolt Dimensions: Diameter & Head Size

Disclaimer: Actual dimensions and tolerances may vary slightly depending on head style, manufacturer, or material — always verify with the official product datasheet before use.

| M2.6 x 0.45 Screw & Bolt – DIN 13-1/ISO 68-1 | ||

|---|---|---|

| Dimension | Size (mm) | |

| Min | Max | |

| Major Diameter | 2.48 | 2.58 |

| Pitch Diameter | 2.217 | 2.288 |

| Minor Diameter | 1.94 | 2.093 |

| Thread Pitch | 0.45 | |

| Major Diameter | 2.48 | 2.58 |

| Pitch Diameter | 2.243 | 2.288 |

| Minor Diameter | 1.966 | 2.093 |

| Thread Pitch | 0.45 | |

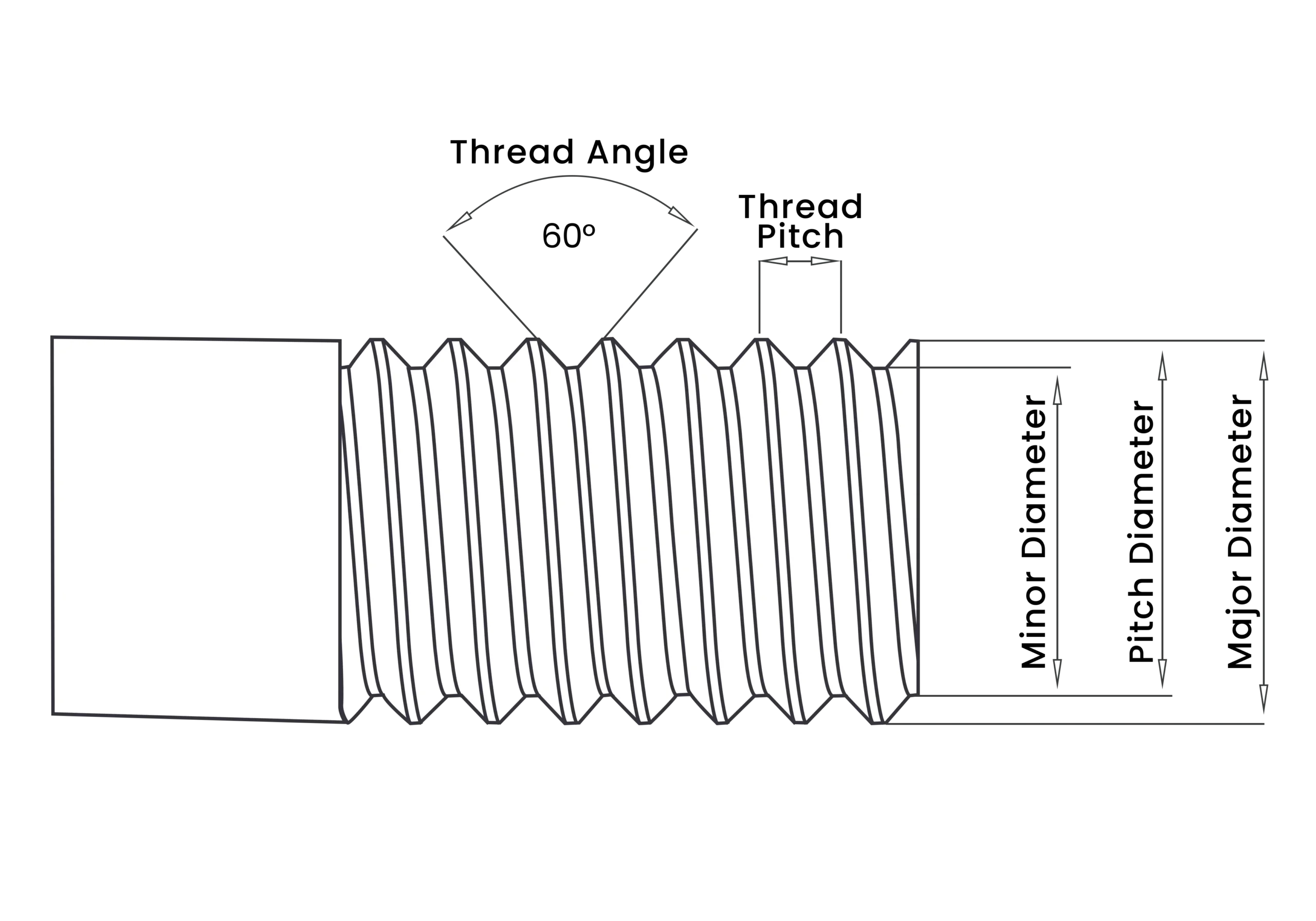

- Major Diameter – The largest diameter of the external thread, measured crest to crest. This defines the nominal size (e.g., M12 which is 12 mm of nominal major diameter).

- Pitch Diameter – The diameter of an imaginary cylinder where the thread thickness equals the space between threads. This is the critical dimension for thread fit (Tolerance classes 2A/3A for Imperial; 6g/4g6g for Metric).

- Minor Diameter – The smallest diameter of the external thread, measured root to root. This represents the core strength of the fastener and is the theoretical maximum diameter of the tap drill.

- Thread Pitch – The distance from a point on one thread to the corresponding point on the next.

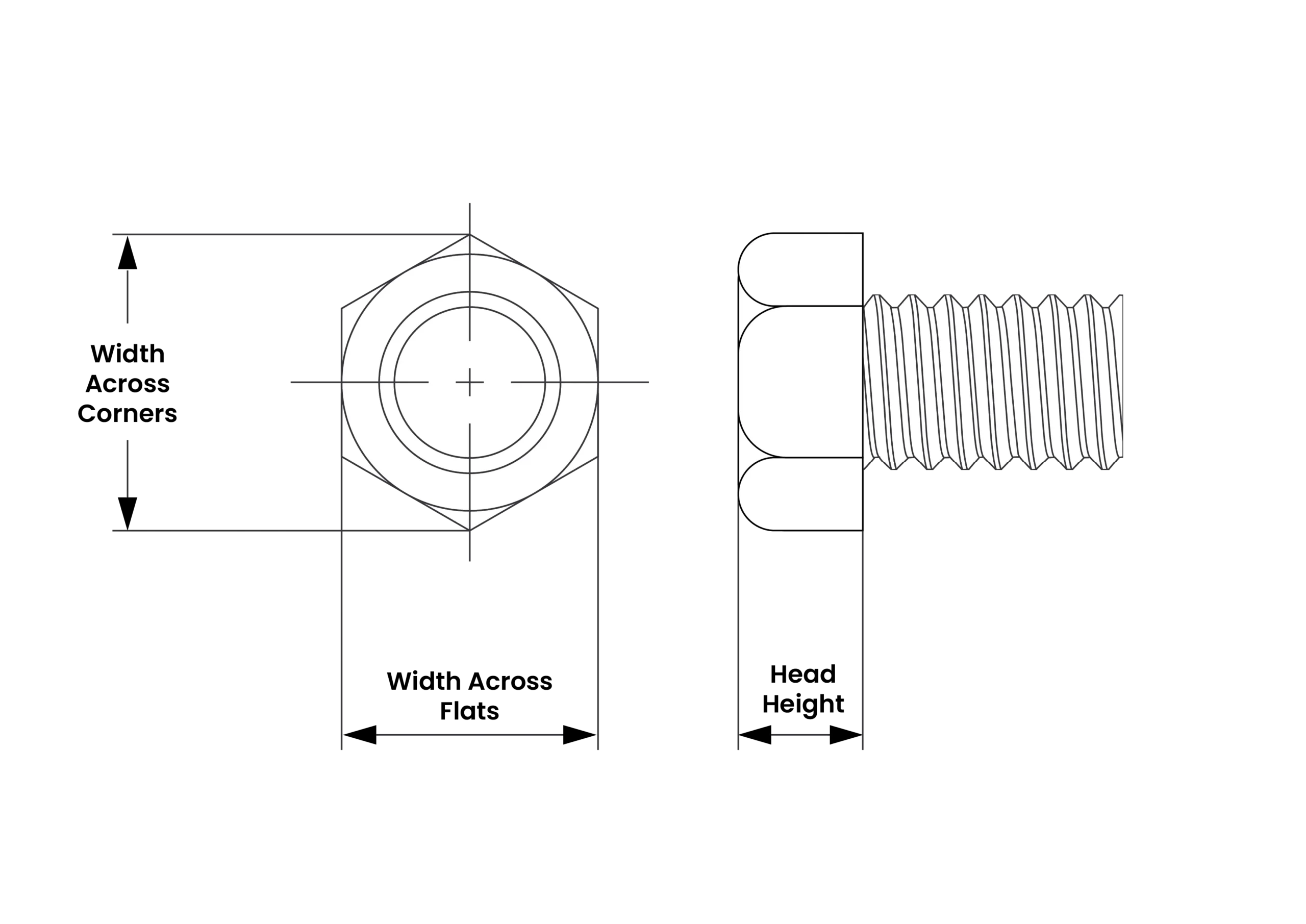

| Hex Head – DIN 933/ISO 4017 | ||

|---|---|---|

| Dimension | Size (mm) | |

| Min | Max | |

| Width Across Flats | 5 | 5.18 |

| Width Across Corners | 5.51 | Not specified |

| Head Height | 1.8 | 2.05 |

| Metric to Inch Converter | |

|---|---|

| Enter mm to convert to inches | |

Frequently Asked Questions

What is the tap drill size for M2.6 x 0.45 screws or bolts?

For metric fasteners, the recommended tap drill size can be calculated using this formula: Major Diameter – Thread Pitch

Therefore, for an M2.6 x 0.45 screw or bolt, the recommended tap drill is 2.15mm. This provides the necessary clearance for tapping internal threads while maintaining structural integrity.

What clearance hole size is needed for an M2.6 screw or bolt?

For a Close Fit, a 2.80mm drill bit is utilized. For a Normal Fit, a 2.90mm bit is used, and for a Loose Fit, a 3.20mm bit is recommended to allow the fastener body to pass through the assembly without interference.

What is the difference between a bolt and a screw?

The difference is based on the intent of the fastener’s use; If the primary intent is for the fastener to pass through an unthreaded hole and be assembled with a nut, it is a Bolt. In this application, you usually hold the head and turn the nut to apply tension. But if the primary intent is for the fastener to be installed into a threaded (tapped) hole, it is a Screw. In this application, the connection is tightened by turning the head of the fastener itself.