M64 Washer Dimensions & Size

M64 size is usually specified by the Normal Series (DIN 125A / ISO 7089), which is the industry standard for general heavy engineering and structural applications. Based on these standards, M64 washers typically feature a hardness of 200 HV or 300 HV (Vickers Hardness), providing the structural integrity required to prevent deformation or “cupping” under the massive clamping forces of high-tensile structural bolts.

Note: While these values reflect standard manufacturer datasheets, actual dimensions and tolerances may vary based on material (e.g., Stainless Steel vs. Hot-Dip Galvanized Steel) and manufacturing class. Always verify with the official product datasheet for critical applications.

| M64 Standard Series Washer – DIN 125A/ISO 7089 | ||

|---|---|---|

| Dimension | Size (mm) | |

| Min | Max | |

| Inner Diameter | 66 | 66.74 |

| Outside Diameter | 113.6 | 115 |

| Thickness | 8 | 10 |

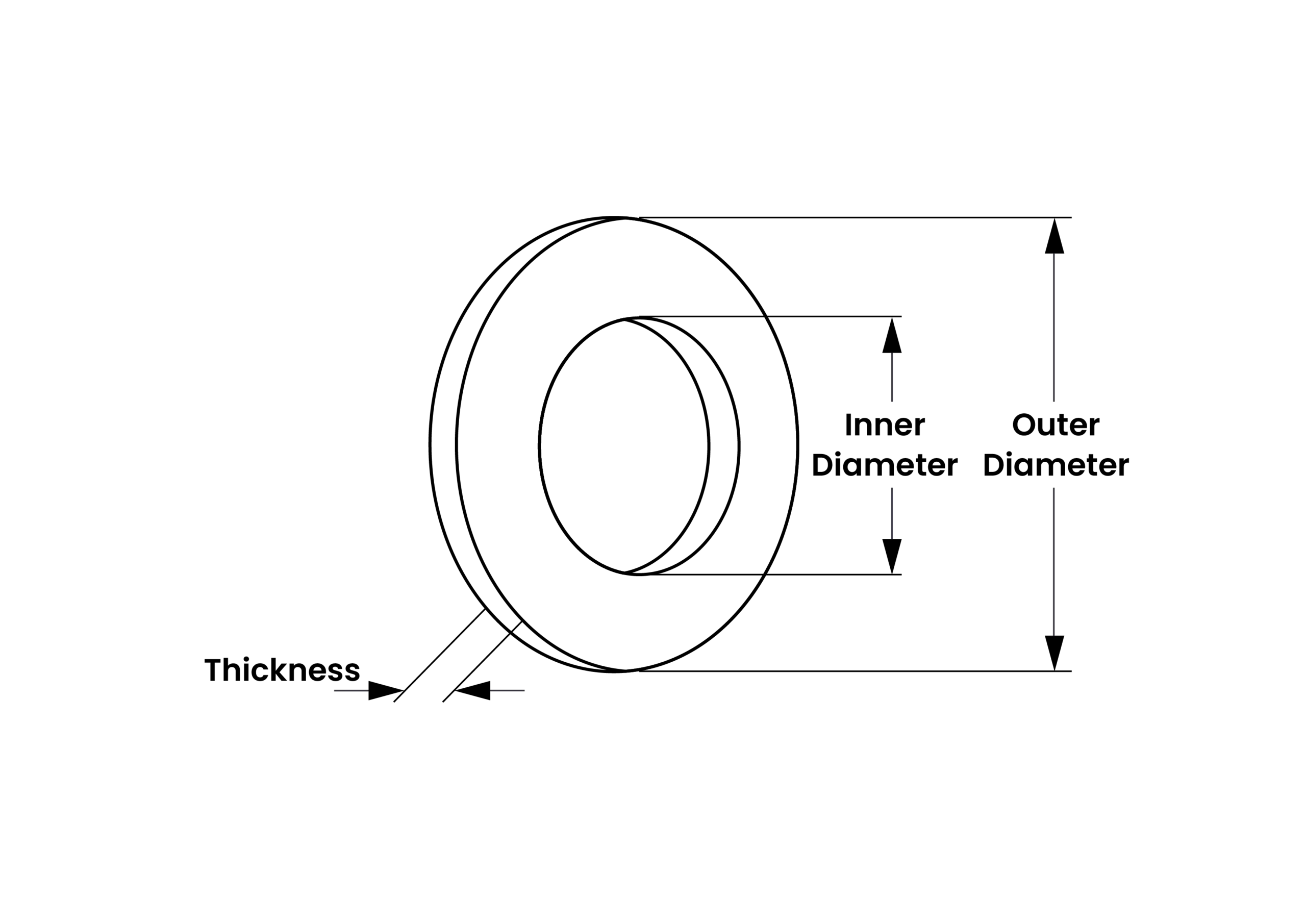

- Inner Diameter – The diameter of the hole, designed to clear the bolt/screw thread.

- Outside Diameter – The total width of the washer, determining the load distribution area.

- Thickness – The height of the washer, providing the spacing and structural support.

| Metric to Inch Converter | |

|---|---|

| Enter mm to convert to inches | |

| Previous & Next Size Chart |

|---|

| ← M60 |

Frequently Asked Questions

What does the “M64” designation mean on a washer?

The “M” stands for Metric, and the number represents the nominal thread diameter of the screw or bolt. An M64 washer is designed specifically for fasteners with a 64 mm nominal major diameter.

What is the difference between Form A and Form B washers?

The difference lies in the outer edge finish. Form A washers have a square, flat edge and are the most common. Form B washers include a 30° to 40° chamfer (beveled edge) on one side, according to DIN 125B and ISO 7090 standards.

What standard is used for M64 washers?

M64 washers in this technical guide follow the Normal Series (DIN 125A / ISO 7089) standard. This is the industry benchmark for flat washers used with large hexagon bolts in structural and mechanical projects.

What does the HV rating mean on a washer?

HV stands for Vickers Hardness. For M64 fasteners, a rating of 200 HV or 300 HV is typical for steel and stainless steel. This ensures the washer resists the intense indentation forces generated during the high-torque installation of heavy-duty structural bolts.

In which materials are M64 washers commonly available?

M64 washers are most frequently produced in Hot-Dip Galvanized Steel for outdoor structural applications due to superior corrosion resistance. They are also available in A4 (316) Stainless Steel for marine environments and Plain (Black) Steel for heavy industrial machinery.