M52 Bolt & Screw Dimensions: Diameter & Head Size

Disclaimer: Actual dimensions and tolerances may vary slightly depending on head style (e.g., Heavy Hex, Stud Bolts, Anchor Bolts), manufacturer, or material grade — always verify with the official product datasheet before use.

| M52 x 5.0 Screw & Bolt – DIN 13-1/ISO 68-1 | ||

|---|---|---|

| Dimension | Size (mm) | |

| Min | Max | |

| Major Diameter | 51.399 | 51.929 |

| Pitch Diameter | 48.445 | 48.681 |

| Minor Diameter | 45.365 | 46.516 |

| Thread Pitch | 5.0 | |

| Major Diameter | 51.399 | 51.929 |

| Pitch Diameter | 48.531 | 48.681 |

| Minor Diameter | 45.451 | 46.516 |

| Thread Pitch | 5.0 | |

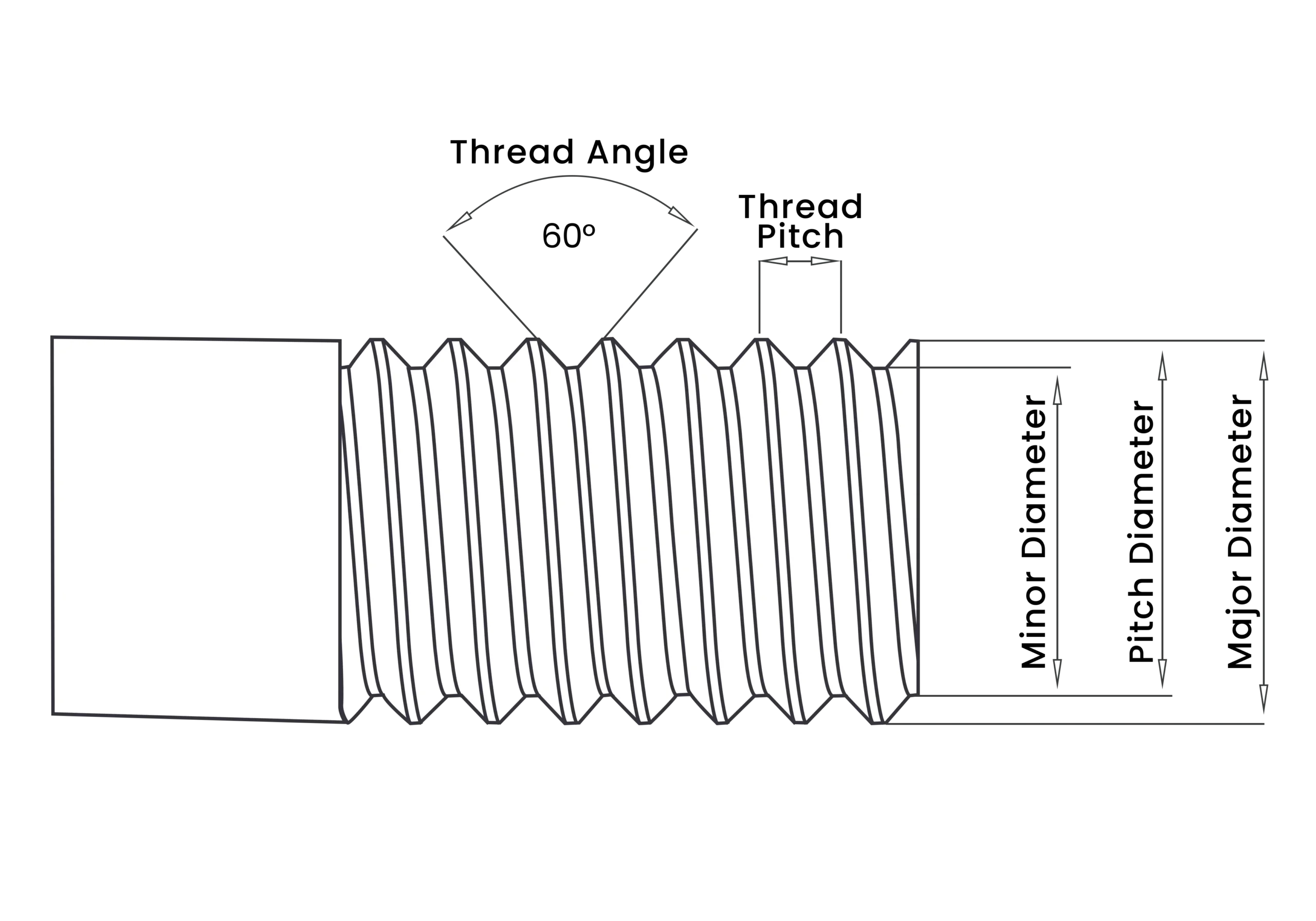

- Major Diameter – The largest diameter of the external thread, measured crest to crest. This defines the nominal size (e.g., M12 which is 12 mm of nominal major diameter).

- Pitch Diameter – The diameter of an imaginary cylinder where the thread thickness equals the space between threads. This is the critical dimension for thread fit (Tolerance classes 2A/3A for Imperial; 6g/4g6g for Metric).

- Minor Diameter – The smallest diameter of the external thread, measured root to root. This represents the core strength of the fastener and is the theoretical maximum diameter of the tap drill.

- Thread Pitch – The distance from a point on one thread to the corresponding point on the next.

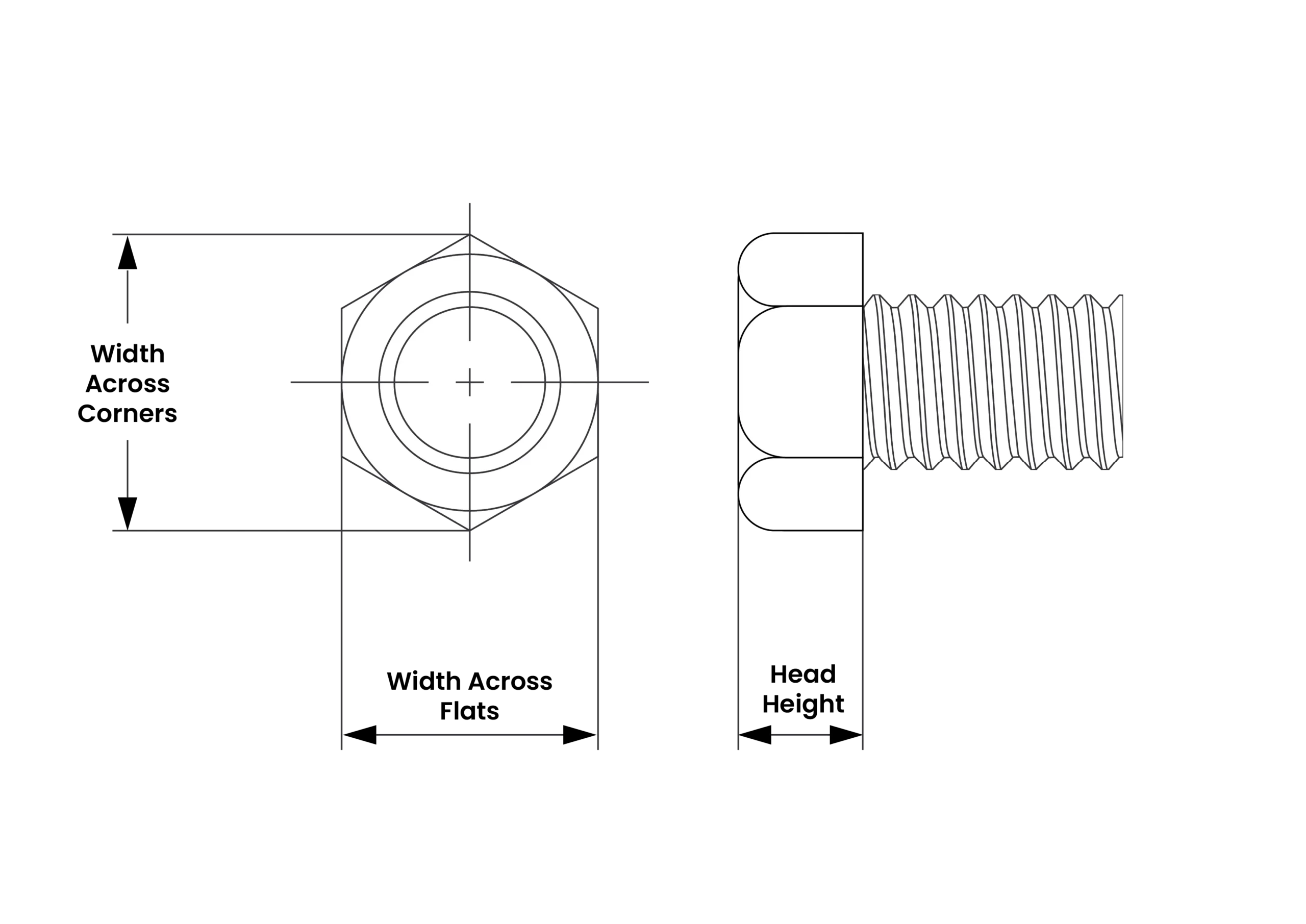

| Hex Head – DIN 933/ISO 4017 | ||

|---|---|---|

| Dimension | Size (mm) | |

| Min | Max | |

| Width Across Flats | 78.1 | 80 |

| Width Across Corners | 88.25 | Not specified |

| Head Height | 32.5 | 33.5 |

| Metric to Inch Converter | |

|---|---|

| Enter mm to convert to inches | |

Frequently Asked Questions

What is the tap drill size for M52 coarse screws or bolts?

For metric fasteners, the recommended tap drill size can be calculated using this formula: Major Diameter – Thread Pitch. For an M52 x 5.0 (Coarse), the recommended tap drill is 47.00mm.

What clearance hole size is needed for an M52 screw or bolt?

For an M52 fastener, a 54.00mm drill bit is utilized for a Close Fit, a 56.00mm bit is used for a Normal Fit, and a 62.00mm bit is recommended for a Loose Fit. A Normal Fit is the industry standard to ensure the massive bolt shank passes through the assembly without binding while maintaining structural alignment.

What is the difference between a bolt and a screw?

The difference is based on the intent of the fastener’s use; If the primary intent is for the fastener to pass through an unthreaded hole and be assembled with a nut, it is a Bolt. In this application, you usually hold the head and turn the nut to apply tension. But if the primary intent is for the fastener to be installed into a threaded (tapped) hole, it is a Screw. In this application, the connection is tightened by turning the head of the fastener itself.