M14 Nut Dimensions: Hex & Thin Series

This charts covers both the Regular Series (DIN 934 / ISO 4032) for standard load-bearing applications and the Thin or Half Series (DIN 439 / ISO 4035), which is ideal for jam nut or lock nut configurations or applications with limited vertical clearance. The thread dimensions comply with DIN 13-1 (coarse), DIN 13-21 (fine series), and ISO 68-1 standards to ensure a precise fit and reliable engagement across heavy-duty metric fastening systems.

Disclaimer: Actual dimensions, including the width across flats (spanner or wrench size), nut height, and thread tolerance may vary depending on the specific manufacturing class and material — always verify with the official product datasheet before use or buying.

| M14 x 2.0 Hex Nut – DIN 13-1/ISO 68-1 | ||

|---|---|---|

| Dimension | Size (mm) | |

| Min | Max | |

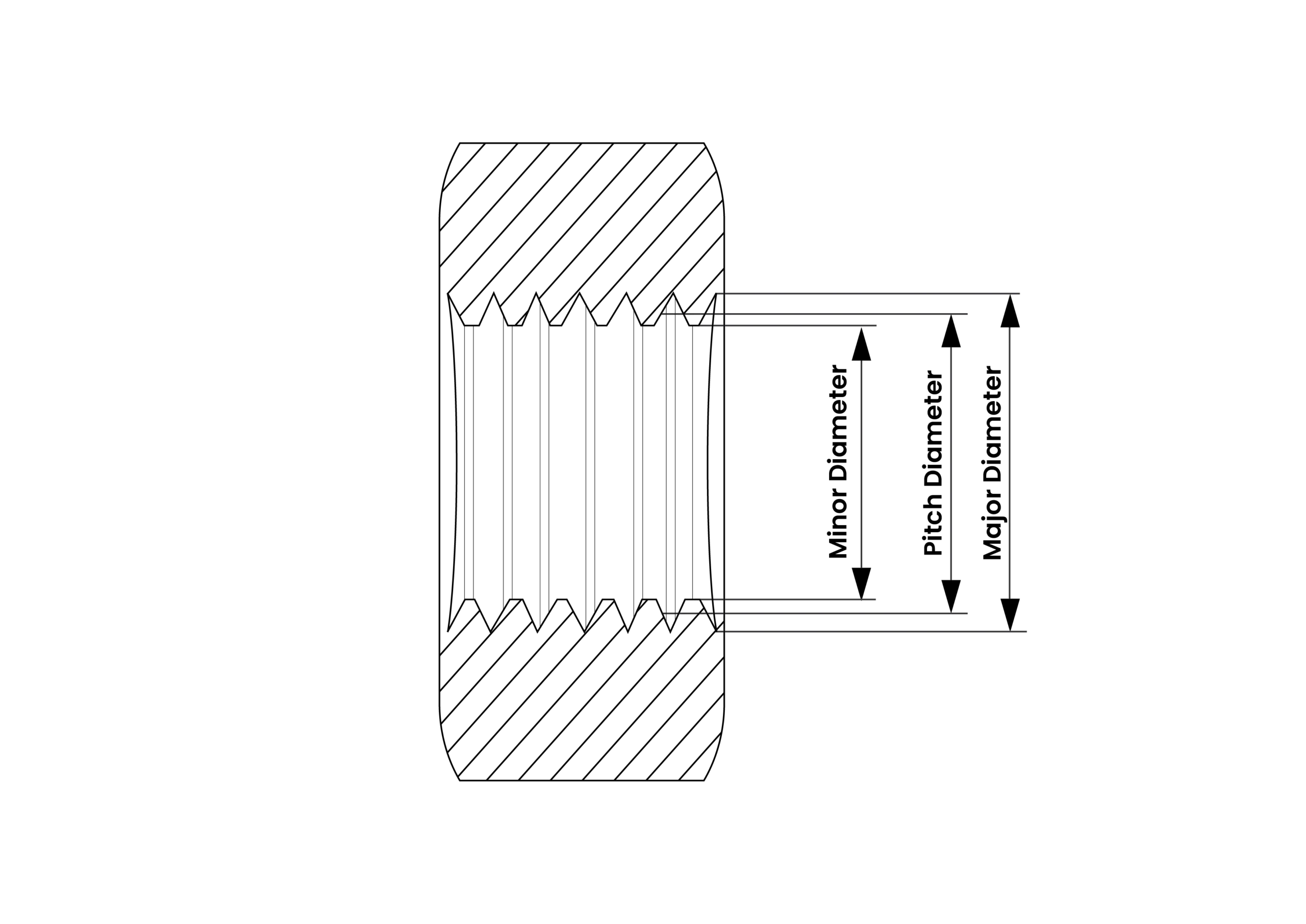

| Major Diameter | 14 | 14.501 |

| Pitch Diameter | 12.701 | 12.913 |

| Minor Diameter | 11.835 | 12.21 |

| Thread Pitch | 2.0 | |

| M14 x 1.5 Hex Nut – DIN 13-21/ISO 68-1 | ||

|---|---|---|

| Dimension | Size (mm) | |

| Min | Max | |

| Major Diameter | 14 | 14.406 |

| Pitch Diameter | 13.026 | 13.216 |

| Minor Diameter | 12.376 | 12.676 |

| Thread Pitch | 1.5 | |

| M14 x 1.0 Hex Nut – DIN 13-21/ISO 68-1 | ||

|---|---|---|

| Dimension | Size (mm) | |

| Min | Max | |

| Major Diameter | 14 | 14.304 |

| Pitch Diameter | 13.35 | 13.51 |

| Minor Diameter | 12.917 | 13.153 |

| Thread Pitch | 1.0 | |

| Metric to Inch Converter | |

|---|---|

| Enter mm to convert to inches | |

Frequently Asked Questions

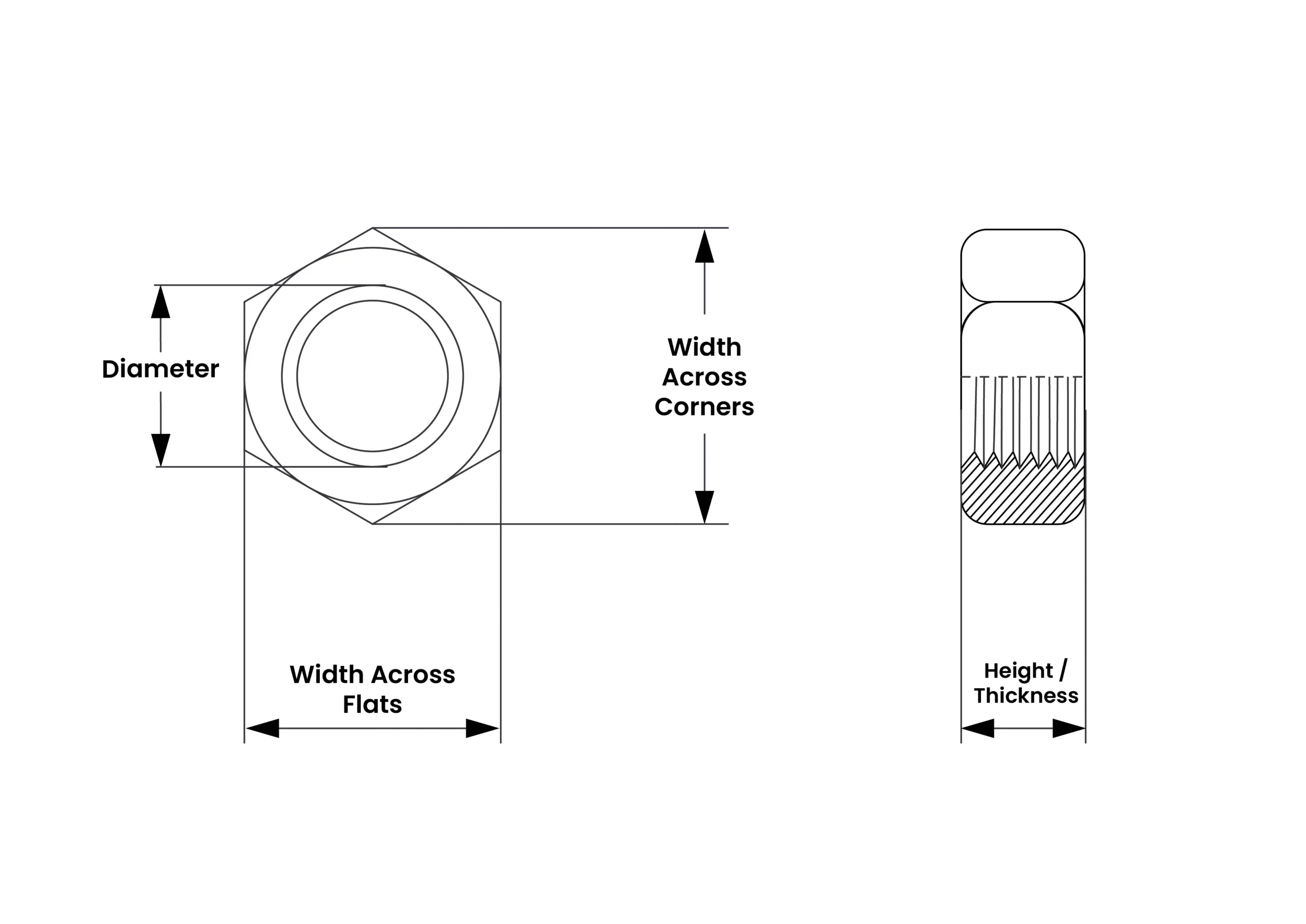

What size wrench or spanner do I need for an M14 nut?

An M14 hex nut typically requires a 21 mm wrench or socket (standard for ISO 4032) or a 22 mm wrench (traditional DIN 934 standard). Due to the high torque often required for M14 fasteners, using a 6-point socket is recommended to prevent rounding the hex flats.

What is a jam nut?

A jam nut is a low-profile hex nut, typically from the Thin Series (DIN 439), that is used to lock a standard nut in place. By tightening a standard nut against a jam nut, you create internal tension between the threads of both nuts and the bolt. This “jams” the assembly together, providing a mechanical lock that prevents loosening caused by vibration or rotation.

Can a Thin Series nut handle the same torque as a Regular nut?

No. Because the Thin Series has fewer threads in contact with the bolt, it has a lower proof load. Applying the high clamping torque required for M14 structural joints to a thin nut will likely strip the threads. Always use a standard height (Regular Series) nut as the primary load-bearing fastener.

Why are Fine Pitch M14 nuts (1.5mm) common in automotive applications?

M14 x 1.5 is a standard wheel lug nut size for many vehicles. Fine threads are preferred in these high-vibration environments because they have a shallower thread angle, which provides better resistance to self-loosening and allows for more precise torque application.